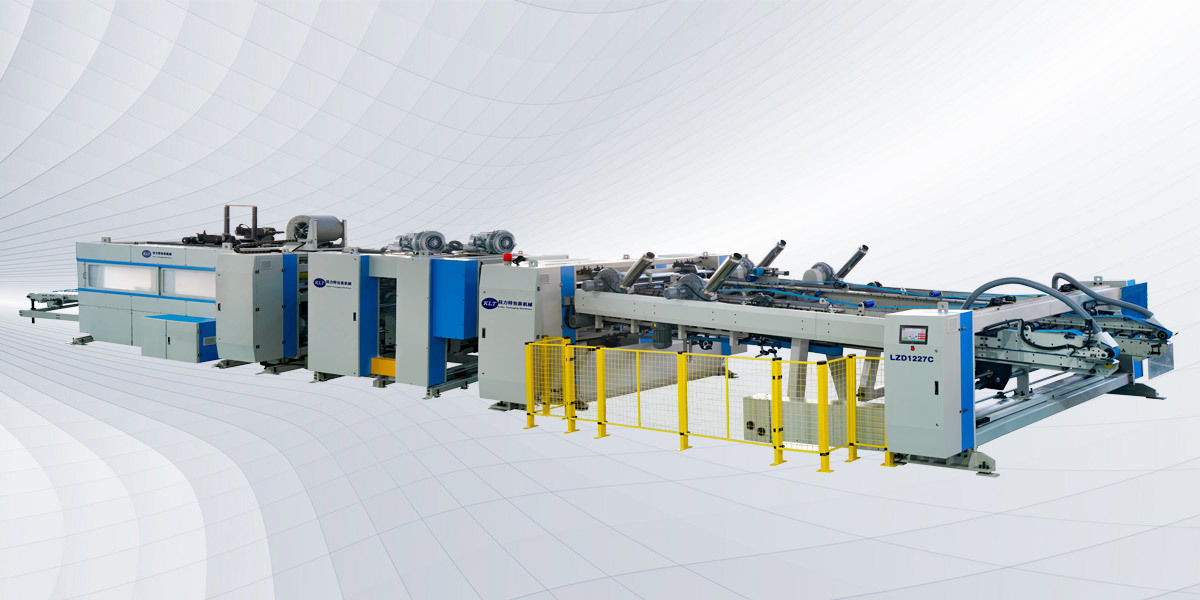

High Speed Adhesive Nail Integrated Intelligent Linkage Line

Product Details

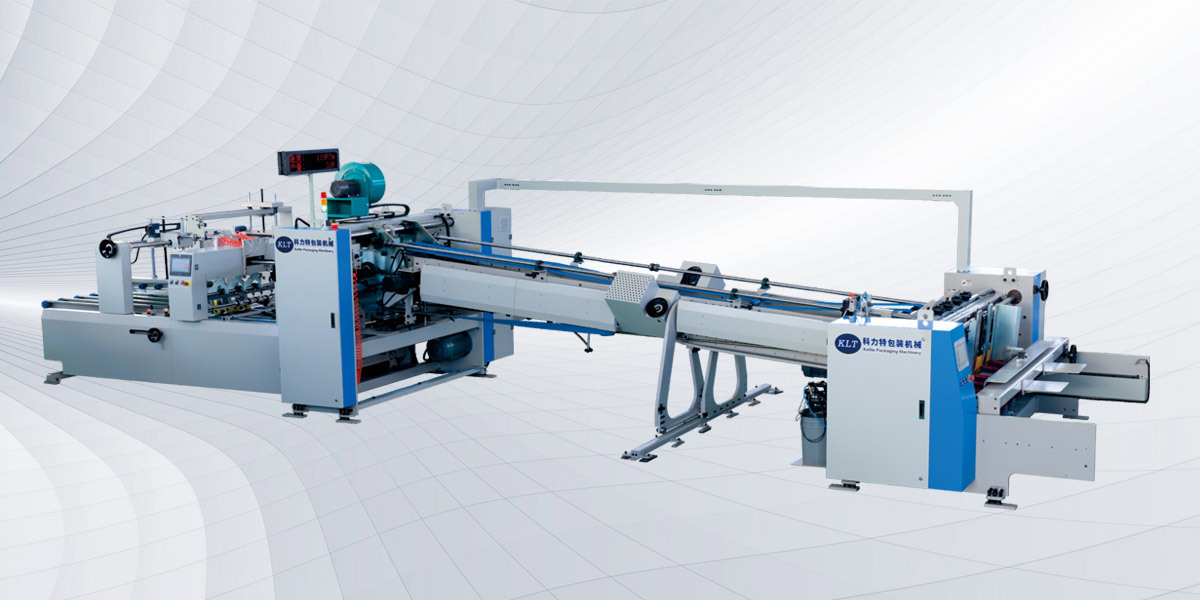

1. A multi-purpose machine (man-made paper and printing machine line switching on demand).

2. Three groups of pre-pressure device function (to correct the problem of cardboard indentation) .

3. The whole adsorption of non-press over paper (to reduce the pressure loss of paperboard).

4. Right angle finishing (finishing department 90 Degrees Standard Fold).

5. Photoelectric detection scissors difference (before the nail box photoelectric sensor detection scissors difference timely warning).

6. Servo automatic tracking deviation correction (correct scissors difference in time, reduce moldingloss).

7. Multi-section side deviation control mouth (effectively control the carton molding gap).

8. Nail box part servo deceleration (shorten empty section over paper to improve nail speed).

9. No need to hitthe paperto damage the carton.

10. Nail box integral movement (accurate synchronous printing machine hanging plate position).

11. Nail head movement (flexible adiustment of the carton nail position).

12. One-button command automatic change orders (printing press one-button command automatic adjustment return).

Installation and commissioning: the buyer shall make every effort to assist the seller in the installation and commissioning period, providing sufficient supporting staff, power, tools and necessary accessories.

| Machine model | LZD1227C | |

| Function | High speed linkage line | Nail box |

| Maximum Speed | 300m/min | 1200 nails/min |

| Paperboard type | Applicable to A, B, C, AB, AC tile, such as three, five layers of corrugated paperboard | |

| Paperboard thickness | 2-10mm | |

| Minimum size of paperboard | 350*720mm | 350*720mm |

| Maximum size of cardboard | 1200*2700mm | 1200*2700mm |

| Size Range | W:170-900mm L:300-900mm W+L:470-1350mm G:≤35mm |

W:170-900mm L:300-900mm W+L:470-1350mm G:≤35mm |

| Suitable for Staple Type | 17# 18# | |

| Overall dimension | 30x4.2x3m(L*W*H) | |

| Machine power | 132KW | |

| Machine weight | 39.4T | |

| Bales numbered | 10、15、20、25、30 | |

Keywords: