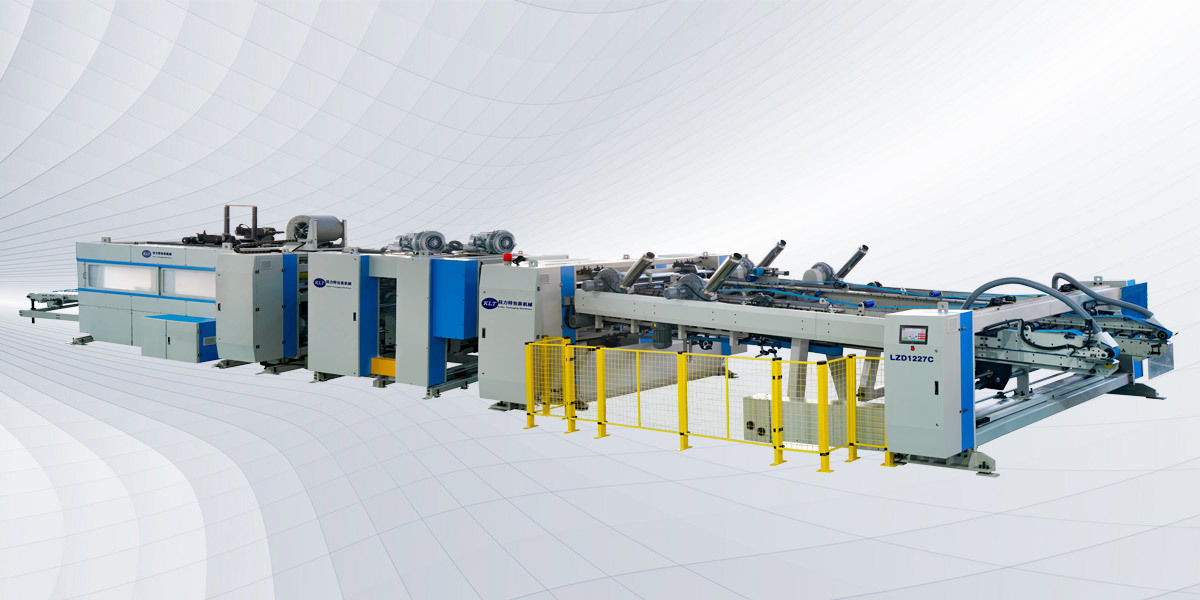

High Speed Adhesive Nail Integrated Intelligent Linkage Line

1. A multi-purpose machine (man-made paper and printing machine line switching on demand). 2. Three groups of pre-pressure device function (to correct the problem of cardboard indentation) . 3. The whole adsorption of non-press over paper (to reduce the pressure loss of paperboard). 4. Right angle finishing (finishing department 90 Degrees Standard Fold). 5. Photoelectric detection scissors difference (before the nail box photoelectric sensor detection scissors difference timely warning). 6. Servo automatic tracking deviation correction (correct scissors difference in time, reduce moldingloss). 7. Multi-section side deviation control mouth (effectively control the carton molding gap). 8. Nail box part servo deceleration (shorten empty section over paper to improve nail speed). 9. No need to hitthe paperto damage the carton. 10. Nail box integral movement (accurate synchronous printing machine hanging plate position). 11. Nail head movement (flexible adiustment of the carton nail position). 12. One-button command automatic change orders (printing press one-button command automatic adjustment return). Installation and commissioning: the buyer shall make every effort to assist the seller in the installation and commissioning period, providing sufficient supporting staff, power, tools and necessary accessories.

View DetailsQZ…B Series Automatic Folder Gluer

1. Controlled by Siemens PLC, the electric devices adopt international brands such as Schneider and Omron to ensure that the control system is stable and reliable; 2. Down foldingfolder gluer is easy to adjust and fast to change order; 3. High qualityimported belts are stable and durable; 4. Accurate paperboard feedingis assured byvacuum suction feedingsystem; 5.Secondary creasing and 90° squaring mechanism make paperboard folding more accurate; 6. Accurate counting; 7. Secondaryflapping structure eliminates fishtail thoroughly; 8. Suitable for cartons with non-woven fabric handle.

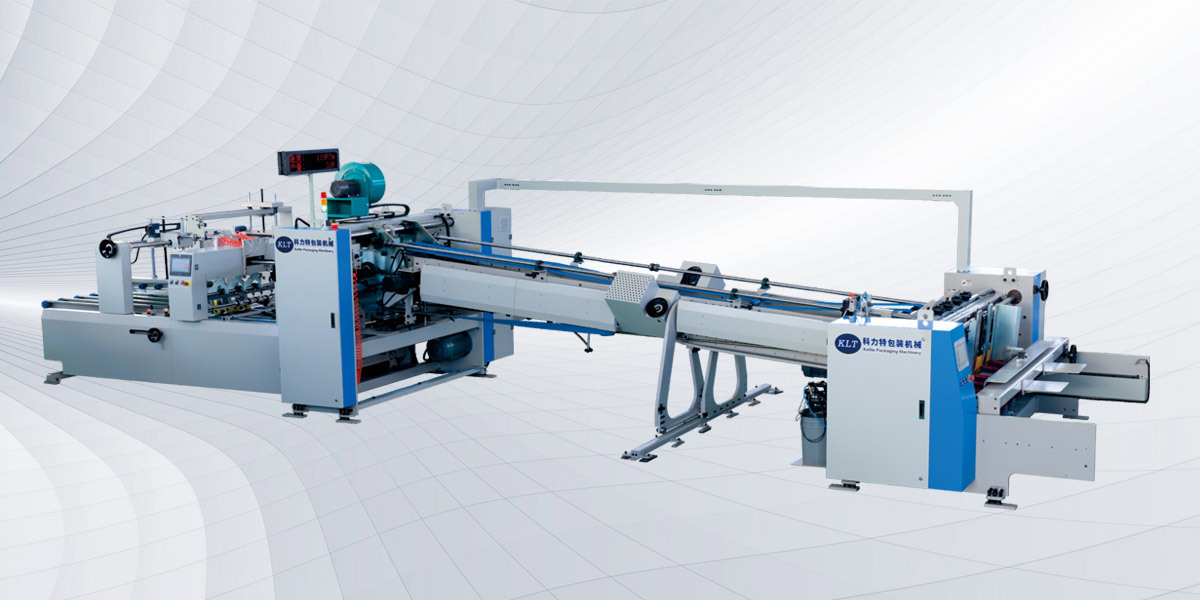

View DetailsLZ…B Series Inline Folder Gluer

Whole machine: 1. Rigidity of whole machine is strengthened, machine is durable in use; 2. Adapts to a wider range ofcardboard and can process narrower and smaller cardboard; 3. High degree of automation, PLC program control, quick to change order. Folding part: 1. The brushes and high pressure blowers are adopted at the entrance to remove the wastes after die cutting and slotting; 2. Longspan folding arm makes paperboard folding mores moothly, and more suitable for large paperboard; 3. Secondary creasing and 90° squaring function effectively improve folding precision; 4. Speed of lower folding belts on both sides is independently adjustable, effectively correcting the fishtail; 5. Suction function of upper folding belt ensures stable cardboard conveying and make box forming more precise.

View DetailsLZ…C Series High Speed Inline Folder Gluer

Whole machine: 1. Rigidity of whole machine is strengthened, machine is durable in use; 2. Strong ability to handle heavy cardboard; 3. High degree of automation, PLC program control, quick to change order; 4. Able to fully interconnect with similar size top printing printer slotter and die cutter. Folding part: 1. The brushes and high pressure blowers are adopted at the entrance to remove the wastes after die cutting and slotting; 2. Long span folding arm folds cardboard more softly, and more suitable forlarge cardboard; 3. Squaring function and V shape forming wheel effectively improve folding precision of cardboard; 4. Speed of lower folding belts on both sides is independently adjustable, effectively correcting the fishtail; 5. Suction function of upper folding belt ensures stable cardboard conveying and make box forming more precise; 6. Automatic precise tension control by pneumatic cylinder, the belts automatically loose up when power off to protect and prolong the service-time of the belts.

View DetailsFull-servo Down-folding High-speed Production Line

1. A multi-purpose machine (man-made paper and printing machine line switching on demand). 2. Three groups of pre-pressure device function (to correct the problem of cardboard indentation) . 3. The whole adsorption of non-press over paper (to reduce the pressure loss of paperboard). 4. Right angle finishing (finishing department 90 Degrees Standard Fold). 5. Photoelectric detection scissors difference (before the nail box photoelectric sensor detection scissors difference timely warning). 6. Servo automatic tracking deviation correction (correct scissors difference in time, reduce moldingloss). 7. Multi-section side deviation control mouth (effectively control the carton molding gap). 8. Nail box part servo deceleration (shorten empty section over paper to improve nail speed). 9. No need to hitthe paperto damage the carton. 10. Nail box integral movement (accurate synchronous printing machine hanging plate position). 11. Nail head movement (flexible adiustment of the carton nail position). 12. One-button command automatic change orders (printing press one-button command automatic adjustment return). Installation and commissioning: the buyer shall make every effort to assist the seller in the installation and commissioning period, providing sufficient supporting staff, power, tools and necessary accessories.

View DetailsTop Loading Stacker Automatic Folder Gluer

Feeding Unit: 1. High negative pressure vacuum suction box feeding system ensures feeding more accurate without skewness; 2. Height of back gauge is adjustable to fit for feeding of warpage board or boxes with non-woven fabrics handle; 3. Glue box is flexibly floated and attached to glue wheel without leakage, less consumption of glue; 4. Use imported high quality diaphragm pump, durable in use; 5. Can use ordinary glue to reduce the cost ofproduction. Folding Unit: 1. Secondary creasing and 90º squaring, function effectively improve folding precision of paperboard, and effectively solved the problem of bursting; 2. Easy adjustment on the folding guide bars and shortens order exchange time, exchange time take sjust 2-3 minutes; 3. Speed oflower folding belts on both sides are independently adjustable by VFD, effectively correcting the fishtail, and prevent the less height boxes from bursting.

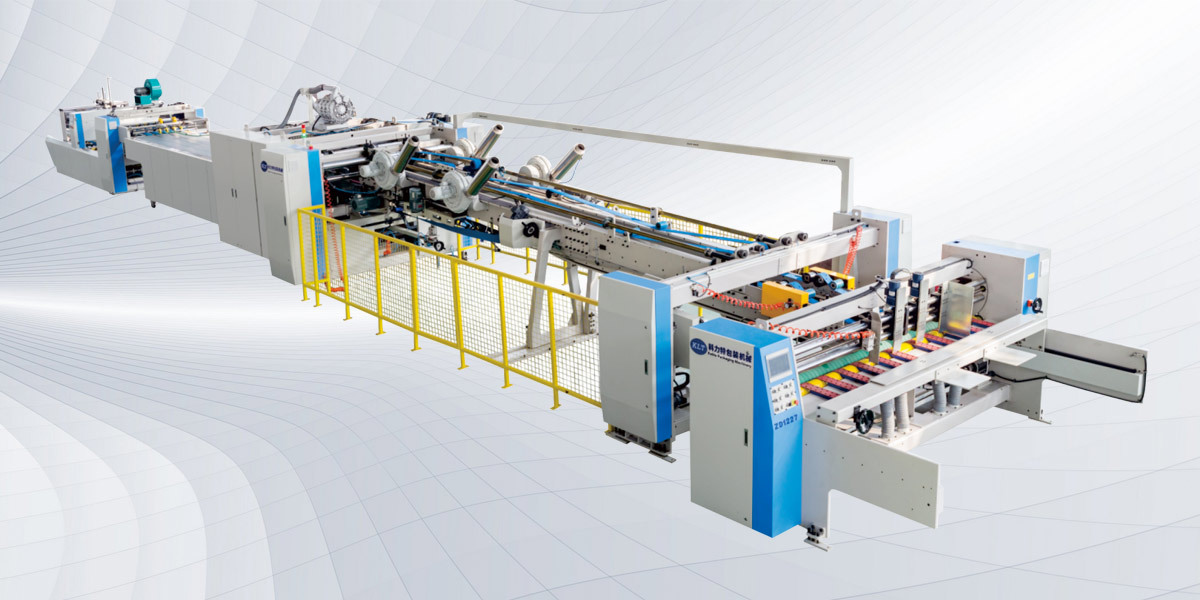

View DetailsQZD1227C Auto Folder Gluer Stitcher Offline

Folding Section: The brushes and high pressure blowers are adopted at the entrance to remove the wastes after diecutting and slotting. Long span folding arm folds cardboard more softly,and more suitable for large cardboard; Squaring function and V shape forming wheel effectively improve folding precision of cardboard; Speed of lower folding belts on both sides is independently adjustable,effectively correcting the fishtail; Suction function of upper folding belt ensures stable cardboard conveying and make box forming more precise. Automatic precise tension control by pneumatic cylinder,the belts automatically loose up when power off to protect and prolong the service-time of the belts. Side Forming Rollers, folding arms are equipped with several groups of side rollers to keep accurate folding, avoiding scissor mouth.

View Details