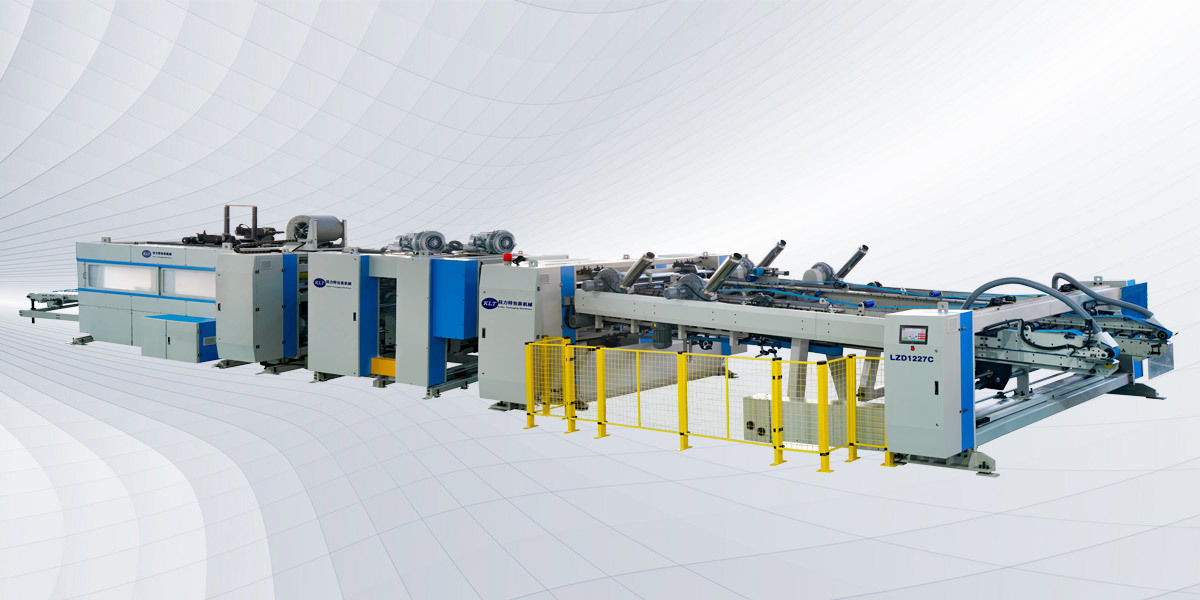

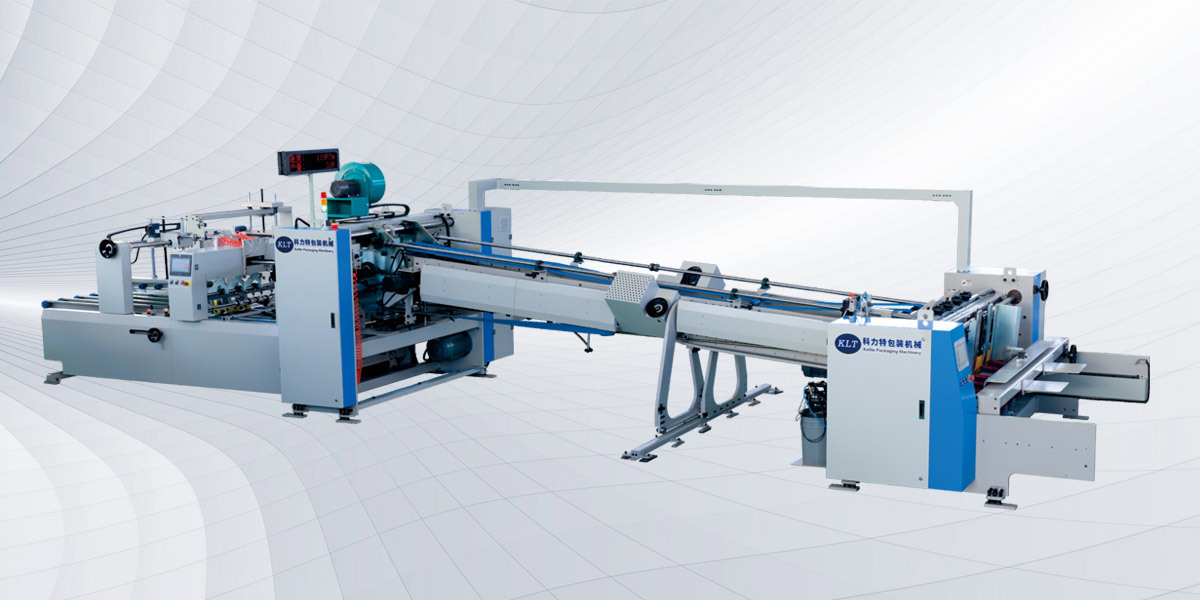

QZD1227C Auto Folder Gluer Stitcher Offline

Product Details

Whole machine:

Rigidity of whole machine is strengthened, machine is durable in use;

Strong ability to handle heavy cardboard with reinforced steel frames;

Higher degrees automation, PLC program control, quick to change orders in 2 minutes;

Able to fully interconnect with similar size any brand top-printing printer, slotter and die cutter.

Imported vacuum suction main belts .

Folding Section:

The brushes and high pressure blowers are adopted at the entrance to remove the wastes after diecutting and slotting.

Long span folding arm folds cardboard more softly,and more suitable for large cardboard;

Squaring function and V shape forming wheel effectively improve folding precision of cardboard;

Speed of lower folding belts on both sides is independently adjustable,effectively correcting the fishtail;

Suction function of upper folding belt ensures stable cardboard conveying and make box forming more precise.

Automatic precise tension control by pneumatic cylinder,the belts automatically loose up when power off to protect and prolong the service-time of the belts.

Side Forming Rollers, folding arms are equipped with several groups of side rollers to keep accurate folding, avoiding scissor mouth.

Gluing Unit:

Glue wheel is driven by independent motor;

Glue box is flexibly floated and attached to the glue wheel without leakage;

Using high performance peristaltic USA-imported gluing-pump for higher stability and durability.

Stitching Unit:

Adopting vibrating stitching/nail head to keep stability and higher speeds.

Stitching/nail unit is separate one, movable left or right wards, enabling accurate nailing/stitching, easily adjustable and reliable.

Down-fixed nailhead, much clean and easy for lubrication maintanance.

One-satge Stacking Unit:

Newly designed one-stage stacking unit, handling blanks/cardboards sheets with high speed, stable, avoid malfunction;

Air blower accelerates cardboard dropping, air volume and wind direction are adjustable;

Deep finishing and flapping mechanism eliminates alignment error of cardboard, flapping frequency adjustable;

Two-stage design of ejecting belt is more stable in cardboard ejection and higher counting accuracy and stability.

Optional configuration:

Automatic glue spraying system;

Glue tank with heating systems during cold weather days;

Multiple waste cleaning/stripping/conveyor system;

Automatic strapping machine, automatic feeder, layer palletizer or robot arm palletizer;

Yellow-colored Safety fences with doors with locks, locking during operation, preventing accidents.

| Machine model | QZD1227C | |

| Function | Single machine adhesive box | Single machine nail box |

| Max. speed | 150m/min | 1200 nails/min |

| Paperboard type | A, B, C, AB, AC etc. 3/5 ply corrugated cardboard | |

| Cardboard thickness | 2-10mm | |

| Minimum size of paperboard | 260*680mm | 400*800mm |

| Maximum size of cardboard | 1200*2700mm | 1200*2700mm |

| Size Range |

W:170-900 L:170-900 W+L:340-1350 G:≤40 |

W:160-900mm L:240-900mm W+L:400-1350mm G:≤40 |

| Overall dimension | 23.5m×4.2×2.1m(L*W*H) | |

| Machine power | 106KW | |

| Machine weight | 32T | |

| Bales numbered | 10, 15, 20, 25, 30 | |

Keywords: